Globe Valve

Globe valves may be used for isolation and throttling services. Although these valves exhibit slightly higher pressure drops than straight through valves they may be used where the pressure drop through the valve is not a controlling factor. Globe valves are extensively employed to control flow. The range of flow control, pressure drop, and duty must be considered in the design of the valve to assure satisfactory service and to avert premature failure Valves subjected to high-differential pressure-throttling service require specially designed valve trim .Generally the maximum differential pressure across the valve disc should not exceed 20 percent of the maximum upstream pressure or 200 psi (1380 kPa), whichever is less. Valves with special trim may be designed for applications exceeding these differential pressure limits.

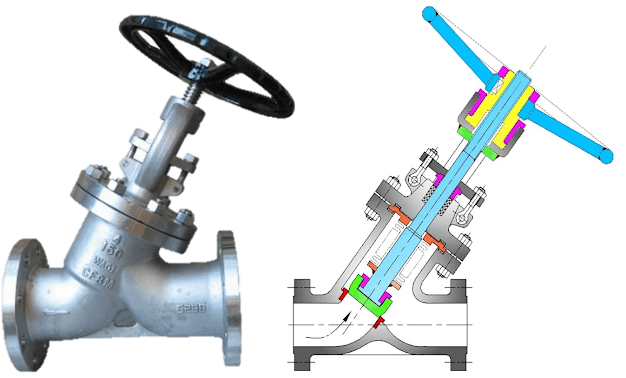

Types of Globe Valves

1) Tee Pattern globe valves have the lowest coefficient of flow and higher pressure drop. They are used in severe throttling services, such as in bypass lines around a control valve. Tee-pattern globe valves may also be used in applications where pressure drop is not a concern and throttling is required.

2) Wye Pattern globe valves, among globe valves, offer the least resistance to flow. They can be cracked open for long periods without severe erosion. They are extensively used for throttling during seasonal or startup operations. They can be rod through to remove debris when used in drain lines that are normally closed.

3) Angle Pattern globe valves turns the flow direction by 90 degrees without the use of an elbow and one extra weld. They have a slightly lower coefficient of flow than wye-pattern globe valves. They are used in applications that have periods of pulsating flow because of their capability to handle the slugging effect of this type of flow.

Construction of a Globe Valve

Globe

valves usually have rising stems, and the larger sizes are of the outside

screw-and-yoke construction. Components of the globe valve are similar to those

of the gate valve. This type of valve has seats in a plane parallel or inclined

to the line of flow.

Maintenance of globe valves is relatively easy, as the discs and seats are readily refurbished or replaced. This makes globe valves particularly suitable for services which require frequent valve maintenance. Where valves are operated manually, the shorter disc travel offers advantages in saving operator time, especially if the valves are adjusted frequently. The principal variation in globe-valve design is in the types of discs employed. Plug-type discs have a long, tapered configuration with a wide bearing surface. This type of seat provides maximum resistance to the erosive action of the fluid stream. In the composition disc, the disc has a flat face that is pressed against the seat opening like a cap. This type of seat arrangement is not as suitable for high differential pressure throttling.

Advantages of a Globe Valve

1. Good shutoff capability

2. Moderate to good throttling capability

3. Shorter stroke (compared to a gate valve)

4. Available in tee, wye, and angle patterns,

each offering unique capabilities

5. Easy to machine or resurface the seats

6. With disc not attached to the stem, valve can be used as a stop-check valve.

Disadvantages of a Globe Valve

1. Higher pressure drop (compared to a gate

valve)

2. Requires greater force or a larger actuator to seat the valve (with pressure under the seat)

3. Throttling

flow under the seat and shutoff flow over the seat

<< READ OTHER INTERESTING POST >>

PIPING SUPPORTS

EXPANSION LOOP CALCULATION

DISTILLATION COLUMN PIPING

PIPE RACK PIPING

TYPES OF GASKET

OIL & GAS PROCESS

HEAT EXCHANGER | |

|

TYPES OF PUMP

TYPES OF DISTILLATION COLUMN

PDMS & E3D COMMANDS

Caesar II Tutorials

COMPRESSOR PIPING

PIPE RACK PIPING

Aveva E3D Tutorials

|

UNDERGROUND PIPING

.jpg)

0 Comments: