CHECKLIST FOR PIPING ISOMETRIC

Piping Isometric drawing is an isometric representation of single line. It is the most important deliverable of piping engineering department.Piping fabrication work is based on isometric drawings. It shows the straight lengths of all the pipe runs on the drawing as clearly as possible. Indicating the line numbers for pipe runs clearly within the drawing. The line number indicates the fluid service, piping class and material, insulation details etc.

Data Required for Checking Piping

Isometric

|

Sr no |

Documents |

Purpose |

|

1 |

P&ID (Piping and Instrumentation Diagram) |

To identify Line Size, Line Number,

instrumentation, valves , insulation and other Special requirements. |

|

2 |

Plot Plan |

To shows the equipment and supporting facilities (pipe racks,

structures, buildings, roads) that are required for the process facility

within a battery limit area. |

|

3 |

Building GA |

To identify Equipment Location &

Orientation. |

|

4 |

Equipment GA |

To check the Nozzle Location &

Orientation , Nozzle size etc |

|

5 |

PMS (Piping Material Specification) |

To check Piping material |

|

6 |

Line List |

To check design Pressure & temperature,

Insulation Requirement, Stress critical Line, hydro test detail,

etc. |

|

7 |

Valve data sheet |

To check valve size , type of actuator, etc. |

P&ID

RELATED

1. Line

number and pipe class.

2.

Flow

direction (including flow direction of check valve)

3.

Min/max

distances, straight lengths, etc. as specified in P&ID.

4.

Removable

spool requirement, if any.

5.

Slope/no

pocket/free draining requirement, if any

6.

Equipment

nozzle/TP numbers and tie-in numbers

7.

Close/open

position for spectacle blind or spacer & blind.

8.

Tag

nos. of equipment, instruments, special items, actuated and manual valves (if

applicable).

LAYOUT RELATED

·

High point vents and low point drains are provided, as per

project requirements, for lines that will be hydro-tested

·

Drains are provided wherever liquid stagnation can occur in the

lines e.g. downstream of a check valve.

·

Adequate pipe spool lengths are provided for wafer type

butterfly and check valves to prevent the interference of the valve disc with

adjacent piping items.

·

The platform/grade/building wall/dyke or bund wall/floor

penetrations and limits of road crossings are properly shown wherever

applicable.

·

The insulation limits are specified appropriately (esp. for

personal protection)

·

Minimum distance between welds is taken as per Project

specifications.

·

Unions are provided in galvanized piping where threaded in-line

items need to be removed for maintenance. Also, unions are provided at regular

intervals in straight pipe runs.

·

Full couplings are provided where applicable for small bore

piping.

·

For piping below 2”, WN flanges are not directly welded to SW

fittings. Also, PE pipes are not directly welded with swaged reducers

(couplings are used in between).

·

Appropriate break-up flanges are provided in piping with

internal lining and hot-dip galvanized piping (based on tub size). Spool

configuration is made with one elbow or one tee only to ensure proper

galvanizing.

·

Lifting lugs are provided for removable spools wherever required

as per project requirements.

·

The piping interfaces with equipment/package nozzles/terminal

points are checked (w.r.t. size, rating, flange face type and nozzle/TP nos.).

·

The electrical tracing requirement and its limits are specified

appropriately.

·

The straight length requirement for suction & discharge

piping for compressors & pumps is as required by Vendor/project specs.

·

The wrapping and coating requirement and its limits are

specified appropriately for u/g lines.

·

Straight lengths and branch configuration of upstream/downstream

lines for anti-surge valves is as per Compressor Vendor’s recommendation.

·

The F/F dimensions of all valves, special items and in-line

instrument items are as per approved vendor drawings.

·

The instrument connections are checked with Piping-Instrument

interface drawings/Instrument hook-up drawings.

·

The straight length requirement (u/s & d/s) has been

provided for flow meters (e.g. flow orifices, flow nozzles, venture meters) and

is as per Project standards/Vendor requirements.

·

Line configuration allows easy removal of spectacle blinds/spacers

& blinds and valves in case of RTJ flange joints.

·

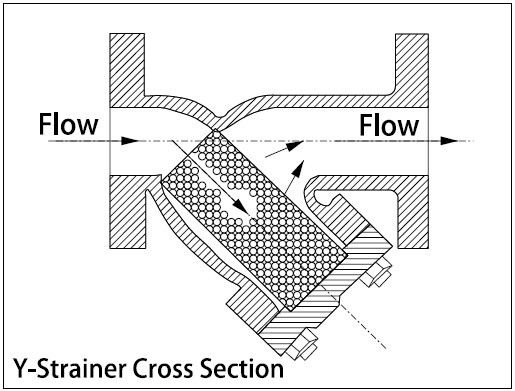

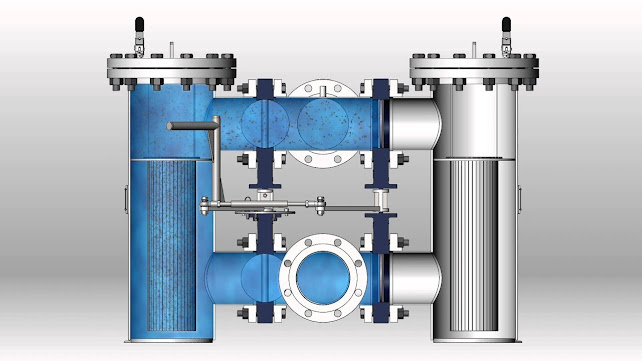

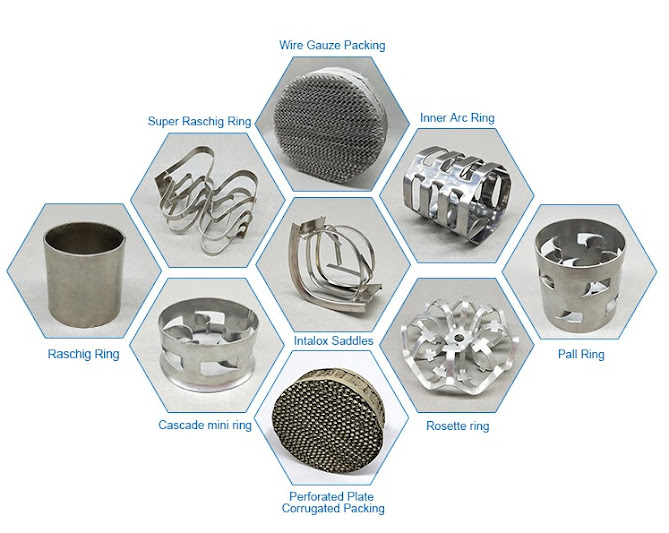

Flanged spools are provided in the case of conical strainers to

enable removal.

·

Orientation of valve handwheel / lever is checked in model for

proper access and commented accordingly

·

Line routing is visually checked in model for general

requirement like access to in line items, supporting, clearances, obstructions,

consistency and aesthetic requirement, etc.

·

Branches like drains, drip legs, etc. are located with

sufficient clearance from the supports, steel or other obstructions so that

they do not clash during expansion/contraction.

· Drip leg size and dimension is checked with Standard drawing for steam line.

CODE AND STANDARD |

Title Block

- Line Number

- Isometric Drawing

Number

- Sheet Number

- P & ID Number

- Piping Layout/GAD Drawing

Number

- Project Name, Project Code and Area

Code

- Insulation and Heat Tracing Type (If the

line is insulated only)

- Line Testing Type.

- Inspection Class

- Hydro-test / Pneumatic test pressure

- Design Pressure and Design Temperature (It’s not mandatory)

Drawing Area

- Iso North

- Equipment name and location

- Co-ordinates for all

equipment

- Nozzle orientation

- Nozzle size and tag

- Angle allocation and direction (clockwise

or anti-clockwise)

- Nozzle centreline elevation

- Line elevations (it can be center line or BOP (Bottom

of Pipe) elevation)

- Line offset angle and

direction

- Slope (if it’s required as per project)

- Line number with complete spec detail

- Spec break (If

required)

- Dimensions of all components and spools

- Fluid flow

direction

- Support locations

- Continuation isometric drawing number (if

the complete line do not fit in the single sheet)

- Instrument location and tagging.

- Valve

orientation

- Control Valve location and

arrangement.

- Orifice Meter straight run

requirement

- Field weld and Workshop weld Identification

BOM [Bill of Materials]

- Component Description

- Component

Quantity

- Commodity

Code

- Valve type and quantity

- Piping component size and rating

- Codes and Standards (Pipe Schedule

Number)

- Non-piping component BOM should not

include on isometric drawing

- Do not include the “on hold”

materials

- Special items, instruments, and pressure

assembly should be tagged

- Spool length and size

1 Comments: